If you are unfamiliar with Protocase, we work with 12,000 designers, engineers and scientists based all over the world. We custom manufacture metal enclosures, components and parts to our customers’ exact specifications, all within our signature 2-3 day turnaround. We could never turn around custom products that fast without the hard work and dedication from our 130 (and counting!) employees, and the vision of our co-founders, Steve Lilley and Doug Milburn.

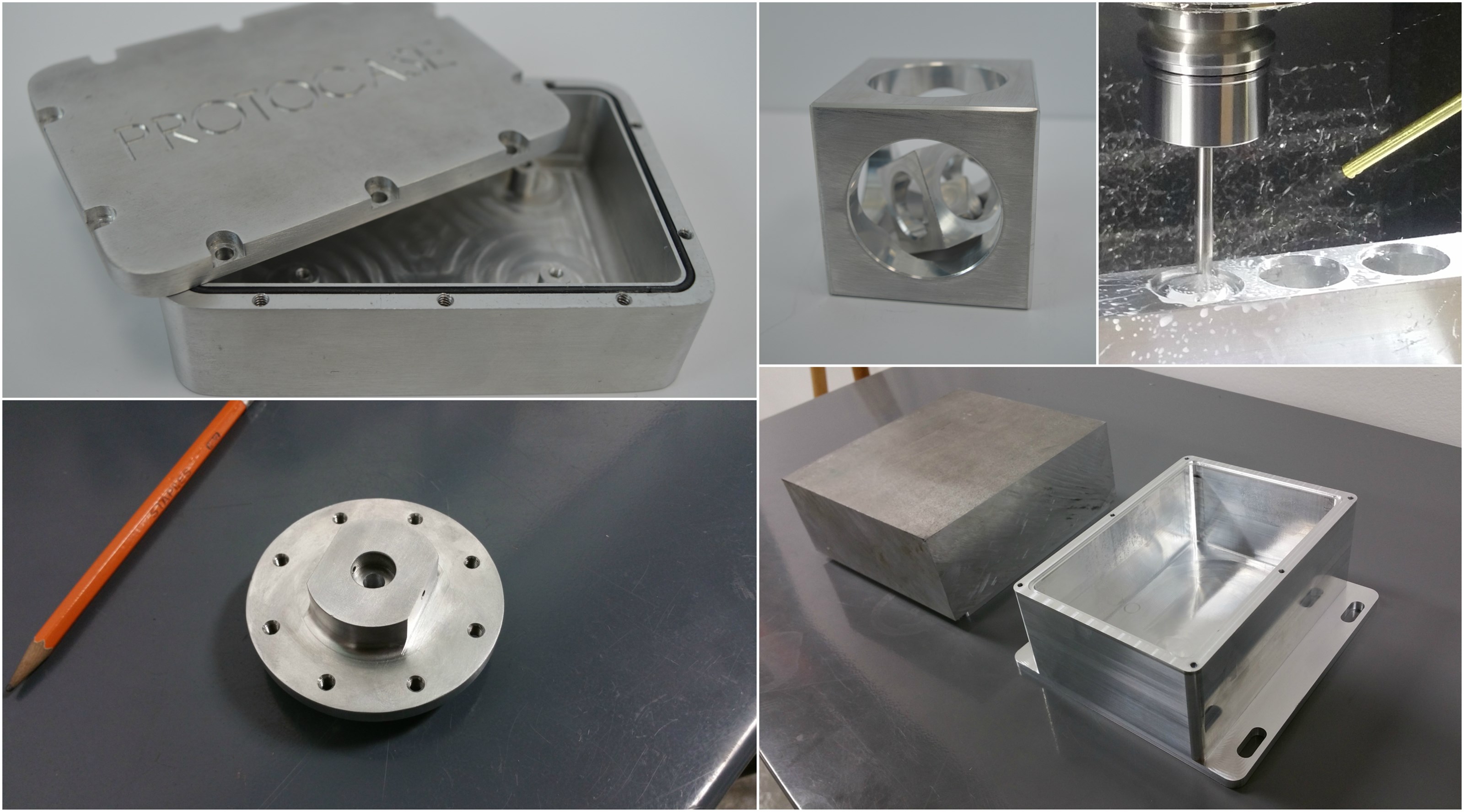

Without getting too far into the nitty-gritty of what we do at Protocase, we make custom metal enclosures, parts and components two ways. For one, we take ultra-thin pieces of sheet metal, cutting it using our fibre laser and then bending into three-dimensional parts and enclosures.

But we also make custom products in our CNC Machining Division. Here, we create custom enclosures, panels and parts by removing material from metal bar stock, or thick pieces of sheet metal.

In both scenarios, we offer our customers all kinds of finishing services so their design looks exactly as they want it to. Fasteners, hardware, chemical coatings, powdercoat paint and graphics – we’ve got it all.

Working at Protocase

This is definitely not your typical workplace, especially when you consider that we work with some of the biggest names in the world, such as Boeing, Lockheed Martín, Callaway Golf, Microsoft, The US Army, Apple, IBM and more. We are a worldwide company based right here in Cape Breton – how amazing is that?

Although I can’t speak for all employees, I know most – if not all – of us are proud to live and work here in beautiful Cape Breton and take pride in working for a company that supports the community in so many ways.

If you’re interested in finding out more about how we support our community, you can read about it here.

However, this past week I’m proud of this company for another reason – we officially became AS9100D certified (and ISO 9001:2015 registered). You’re either super excited like us, or scratching your head asking, “What is that?”

What the heck is AS9100D Certification?

I don’t blame you if you’re not familiar with AS9100 certification. I wasn’t either until I started working at Protocase! The AS9100D certification is a company-level certification for quality management standards, created by SAE International for the Aircraft, Space and Defense industry. This AS9100 certification basically validates Protocase’s status as a custom metal manufacturer for the aerospace industry. Many aerospace companies, along with defense organizations, require AS9100 certification from its suppliers.

Our quality system has been well aligned with the standards required for ISO9001/AS9100 for a long time, but we avoided actually being certified because we thought it might be a drag on our development processes. We have many customers who don’t require this certification from their suppliers.

However, for Shirley, our awesome sales manager – our previous system when it was uncertified meant filling out extremely long paperwork anytime an aerospace company wanted to work with us.

What will it allow Protocase to do?

Now, with our shiny new AS9100D certification, it’s a simple checkmark instead of dealing with a mountain of paperwork. We already work with seven out of the world’s top 10 aerospace companies, and foresee working with many more in the industry. As a result, Protocase is planning a significant expansion of its CNC Machining Division (in which we’ve already ordered another piece of equipment).

This also means we are looking to hire more people! Right now, we’re hiring more people for our CNC Machining Division, including Profile Mill Operators and CNC Machining Technologists/Specialists. We’re also on the hunt for people to join our Engineering and Design Services Team, as well as Sales. If you know someone – whether already based in Cape Breton, or currently living elsewhere – who you think would be a good fit for any of our open positions, please encourage them to check out our website.

We appreciate the support of the Cape Breton community as we continue to grow. Got questions about what we do? Just comment below!

2

Log In or Sign Up to add a comment.- 1

arrow-eseek-e1 - 2 of 2 itemsFacebook Comments